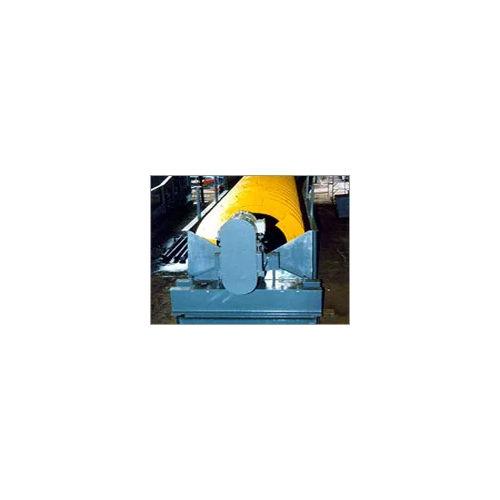

Spiral Classifiers

Spiral Classifiers Specification

- Type

- Spiral Classifiers

- Material

- Stainless steel

- Automatic Grade

- Automatic

- Drive Type

- Electric

About Spiral Classifiers

Our in-house quality inspection department is fully equipped with latest testing equipments, which enables us to manufacture and export certified stock of Spiral Classifiers. These classifiers are used to settle de-water coarse particles from solid stream. Manufactured by using best quality of raw materials at our unit, these classifiers remove settle able solids quickly. The clients can avail our Spiral Classifiers in different specifications as per their requirements. Also, we offer the classifiers at the market leading prices.

Features:

- Easy to install

- High working fluency

- Longer service life

Further Details:

Main Features

|

||||||||||

|

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free